Our Services

We know true quality extends naturally to the delivery of conforming components exactly when expected by the customer. Our team consists of highly skilled, experienced, and certified technicians specially educated in the principles of the company’s rigorous quality assurance procedures, values of integrity, credibility, and a solid commitment to excellence.

In-House Capabilities

-

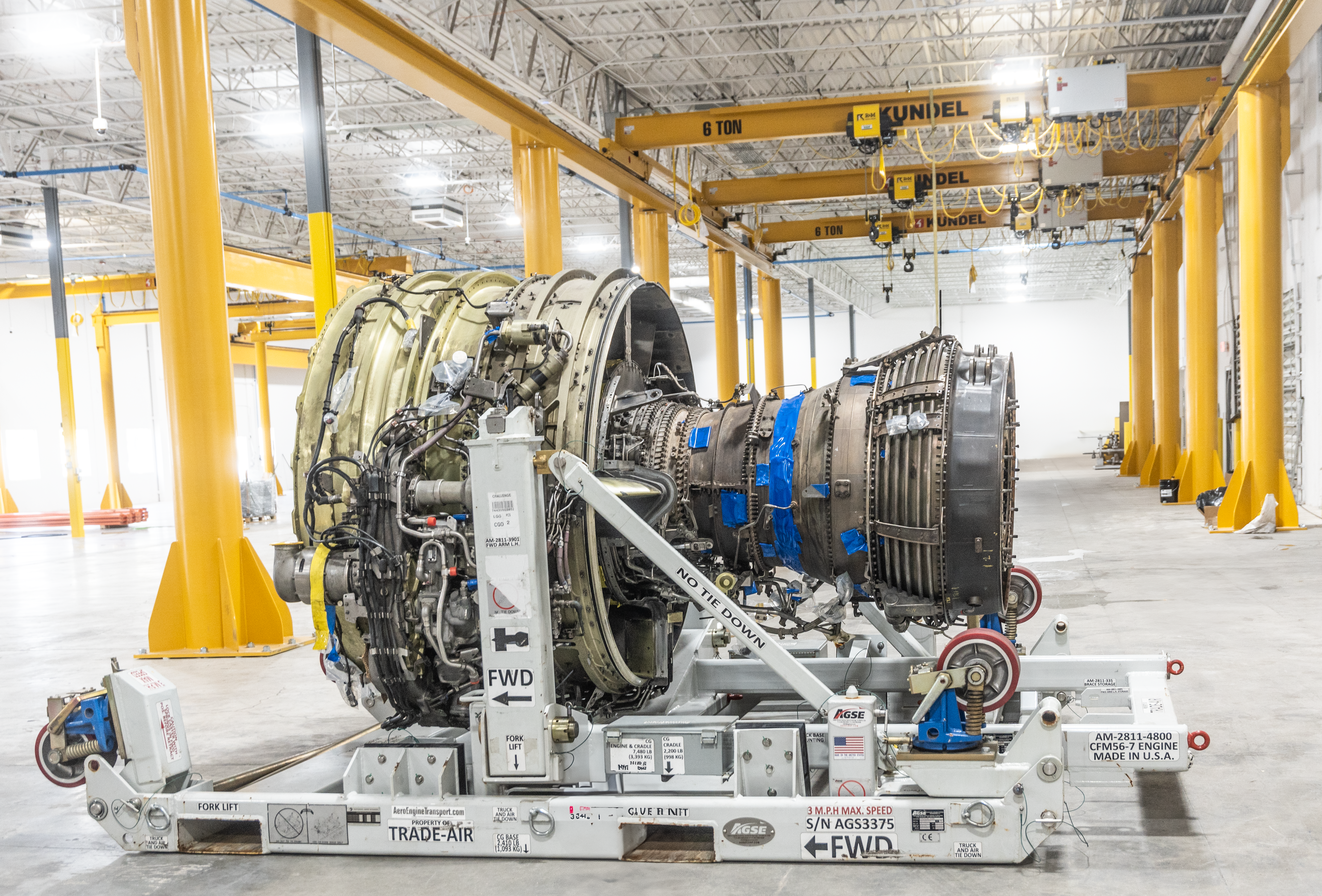

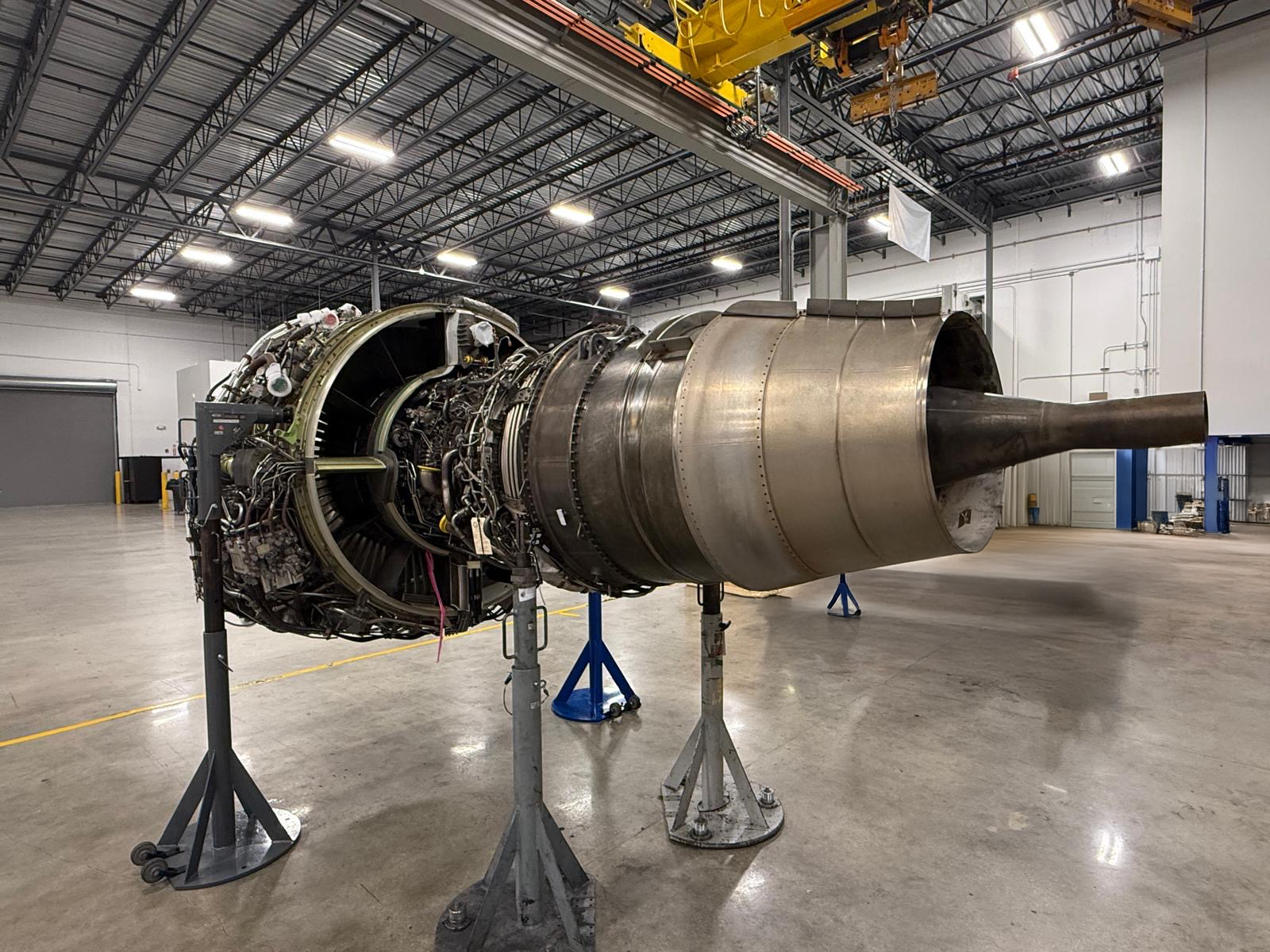

Full Engine Disassembly

-

Full Cleaning Line to Include Ultrasonic and 4-Stepoxide Process

-

ELO/Scan Robot Inspection System (ECI)

-

NDT Inspection and Ultrasonic

-

Detail Inspection Department Including Bearings

-

Rework (Blending, Re-Identifiation, and Refinishing)

-

Fully Capable Machine Shop

-

Static and Dynamic Balancing of all Modules

-

Welding

-

Painting

-

Fuel Nozzles Bench Check

-

Borescope Inspection

-

Boroblend Repairs

Engine Shop Capabilities

-

Borescope Inspections

-

QEC Inventories

-

Boroblend Repairs

-

Fan Blade Re-Lube

-

Vibration Survey and Trim Balance

-

MEC Rigging

-

VSV/VBV Rigging

-

Pull Checks

-

Top Case Repairs

-

Booster Face and Fan Disk Blade Slot Wear Inspection

-

Engine Conversions

-

LRU Replacements

Tailored Engine Repair Workscopes

-

Fully Tailored Engine Workscopes

-

Engine Module Repairs

-

Performance Restorations

-

EGTM Recovery Workscopes

-

SP010/SP020 Workscopes

-

Lease Return Workscopes and MPD Task Cards

-

Advanced Booking of Induction Slots

-

Access to OEM, PMA, and DER Solutions